Measurement Instruments, Inc. is a small business (25 full-time employees) located in Blairsville, PA. Since 1977, Measurement Instruments has been integrating, selling and supporting test, measurement and calibration equipment. The systems integration arm of Measurement Instruments is known as MiTech (Measurement Instruments Technology). MiTech began providing systems to military and commercial markets in 1988. The first project involved a series of testers for the US Army, designed to test a portion of the electrical parameters of a tank. Since that time, our engineers have designed and built a number of systems for military and government applications, including:

– ASTM D9025 Bar and Rod Specimens for Adhesion Tests in Accordance with ASTM D2094

– Model 5076 Calibrator for Inflator Assembly Kit

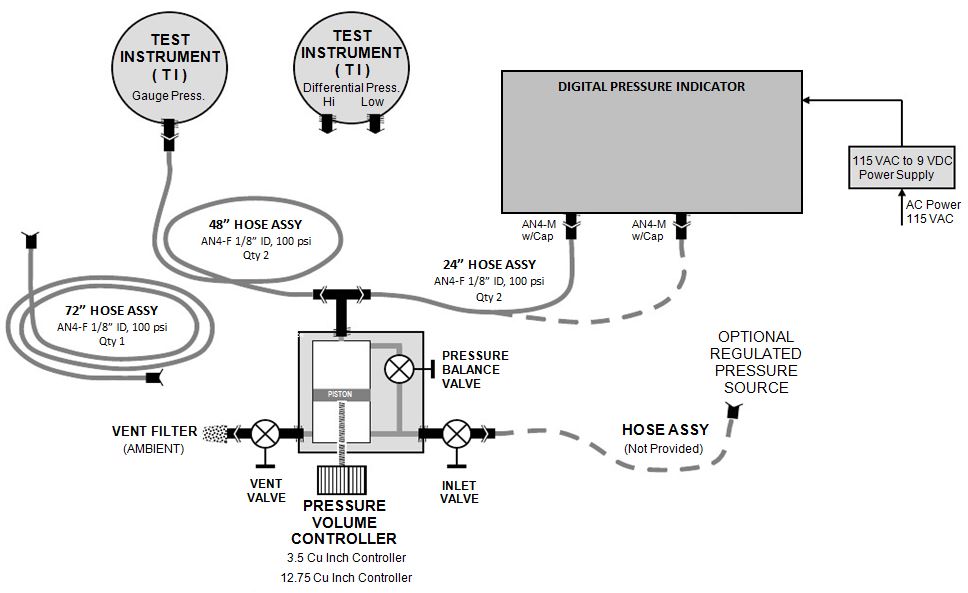

– Very Low Pressure Calibrator (VLPC) for the US Navy.

– Automated HFC43-10 Adsorption Test System (AHATS) built in accordance with MIL-DTL-32130 standard.

– Pressure Calibration Kits consisting of COTS Heise PTE-1 and HQS pressure calibration instrumentation.

– High Precision COTS Mensor Digital Differential Pressure Gauges packaged in accordance with MIL-STD-2073.

– Temperature Triple-Ice-Point-Of-Water Calibration Systems for the US Air Force.

– Pneumatic Test and Data-Acquisition Systems for Parker Hannifin Corporation.

– Designed Test and Exercise Systems for the newly developed Electronic-Throttle-Body for Visteon Corporation.

– Operator Interface and Control Panels, utilizing a CAN-Bus communication protocol, for Nordson Corporation.

– US Service Depot for Milacron – Electronic Control Systems, supplying and supporting in excess of 1,000 systems since 1990. Milacron, a manufacturer of plastic injection molding machines, established MiTech as their US Service Depot. All systems are returned to MiTech for repair, and then returned to the Milacron repair service equipment inventory. Sustainability has been a key factor for this account over the years. We have, multiple times, been able to identify, test and qualify replacement components for obsolete components – thus extending indefinitely the life of their system.

The MiTech division of Measurement Instruments is staffed by electrical engineers, mechanical engineers, industrial engineers, instrumentation specialists, technicians and quality assurance personnel.

Our team excels at projects involving:

– System Integration

– Software Development and Integration

– System Design

– Commissioning

– Calibration Equipment

– Calibration Kits

– Requirement Analysis & Specification Development

– Assembly, Testing, Burn-In

– Compatibility Verification

– Custom Branding

– Sheet-Metal Fabrication

– Technical Support

Engineering assistance, custom cabling, custom packaging, and friendly support are some of the MiTech key elements that our customers have found to be extremely valuable.

MEASUREMENT INSTRUMENTS, INC.

CAGE CODE: 0PRS9

DUNS: 068765288

SBA ID: P0349712